Description

Round Concrete Pole Mold Making Machine

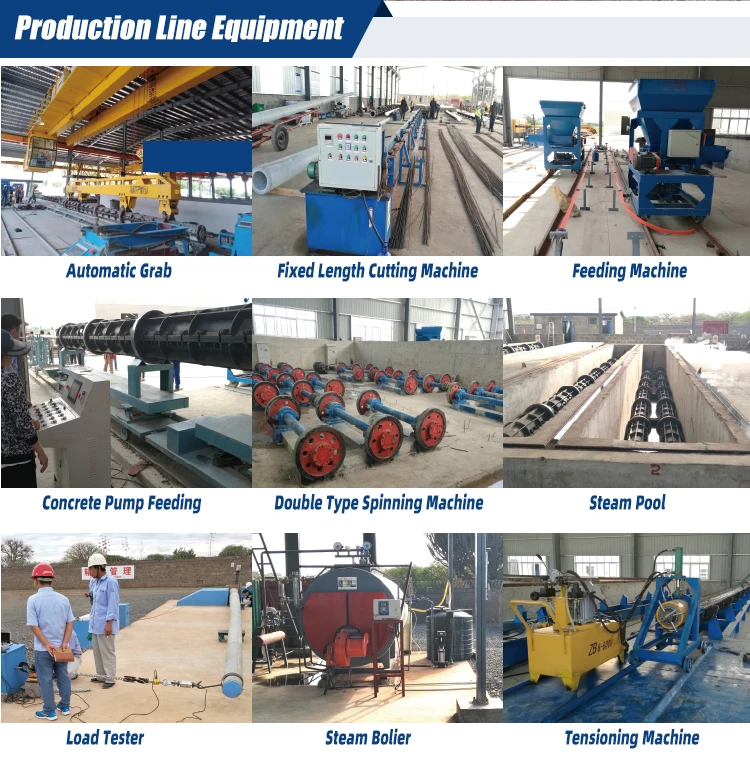

涓€銆丆oncrete electric pole Introduction 1)This machine is a kind of mould equipment, which used for making a variety of different diameter and length of reinforced concrete poles and other cement products. 2)This machine is operated by remote-controlled continuously variable motor. It runs smoothly and has a variable-speed range. So the production of concrete pipes and piles are good at quality. 3)The base of the machine is welded in box-type structure, sturdiness and durability. The bearings are sealed and reliable, long life. Random electric control equipment is complete and easy to use. 2.Concrete electric pole Working Principle 1)Adding the slurry into the mould, it is driven quickly and rotated in the same speed of the machine. Each component is separated and released under the centrifugal force. Usually the higher the slurry rotate speed, the better the slurry separating effect. 2)Centrifugal sedimentation is the use of different density of each component in the slurry, which is rotated under the centrifugal force. To realize the liquid - solid (or liquid - liquid) separation. 3)The speed of separation is slow when the viscosity of slurry is high. 4)It is good for centrifugal sedimentation when the slurry density is different in each component.

Advantages of centrifugal concrete pole mold :

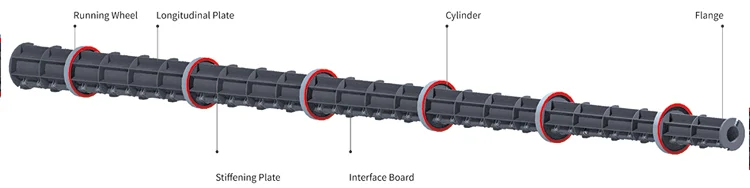

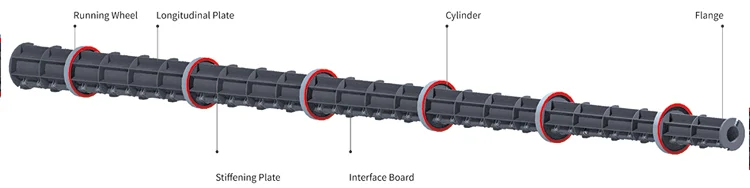

1.Cylinder body: The material blanking according to the customer's order model ,The Maximum single length is 12m , And the cylinder body has less welding seams ,which reduces the influence of weldingdeformation and the error of manual docking

1.Cylinder body: The material blanking according to the customer's order model ,The Maximum single length is 12m , And the cylinder body has less welding seams ,which reduces the influence of weldingdeformation and the error of manual docking

2.Running wheel: The material is adopted 30Mn cold roll forming, with good wearresistance.

3.Welding: It is advisable to adopt the section welding process, the welding method is carbon dioxide shieldedwelding, the gas is mixed gas, and the welding machine adopts Panasonic welding machine, the welding spot is beautiful, and there

is no welding slag.

is no welding slag.

4.Lathe: Introduce CW61180L-16m ultra-long lathe, ∅1000mm×15.4M and below specifications are open for overallprocessing, and the concentricity of the steel mold is better.

5.Anti-leakage grout: Our company uses a planer for a groove at thejoint between the upper mold and the body, and an elastic sealing rubber strip is inserted into the groove. This rubber strip can be reused or replaced at any time. Put an end to the problem of ground joint leakage.

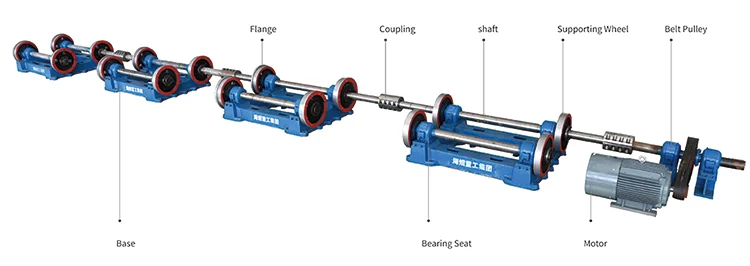

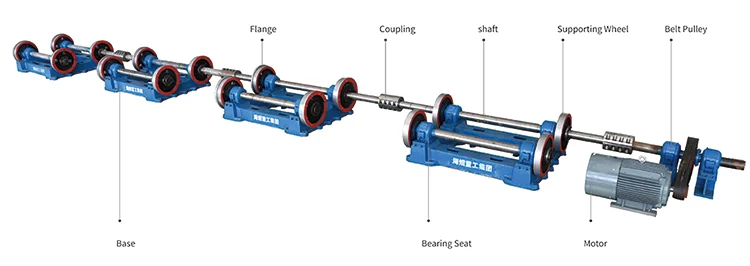

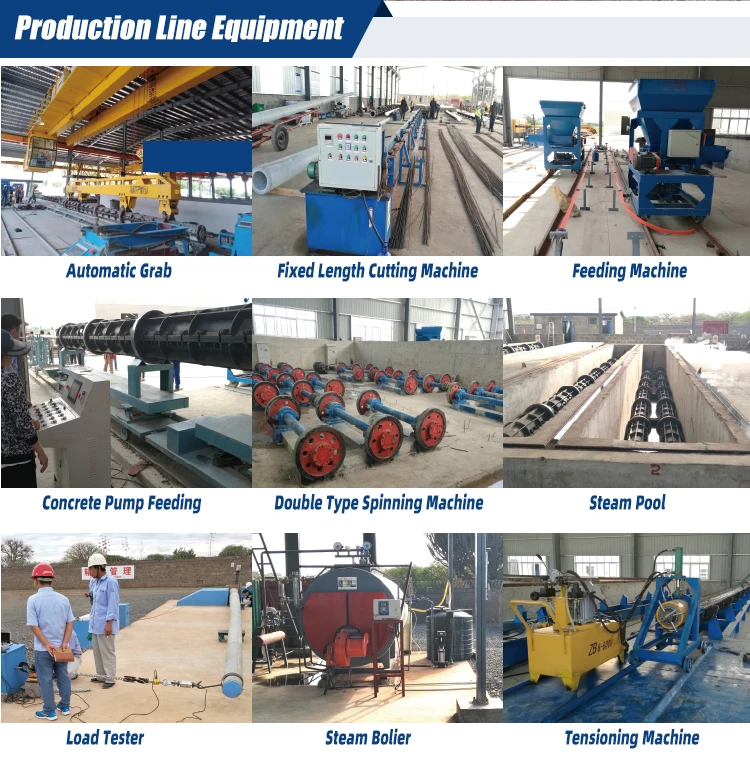

Concrete Pole Centrifuge composition diagram

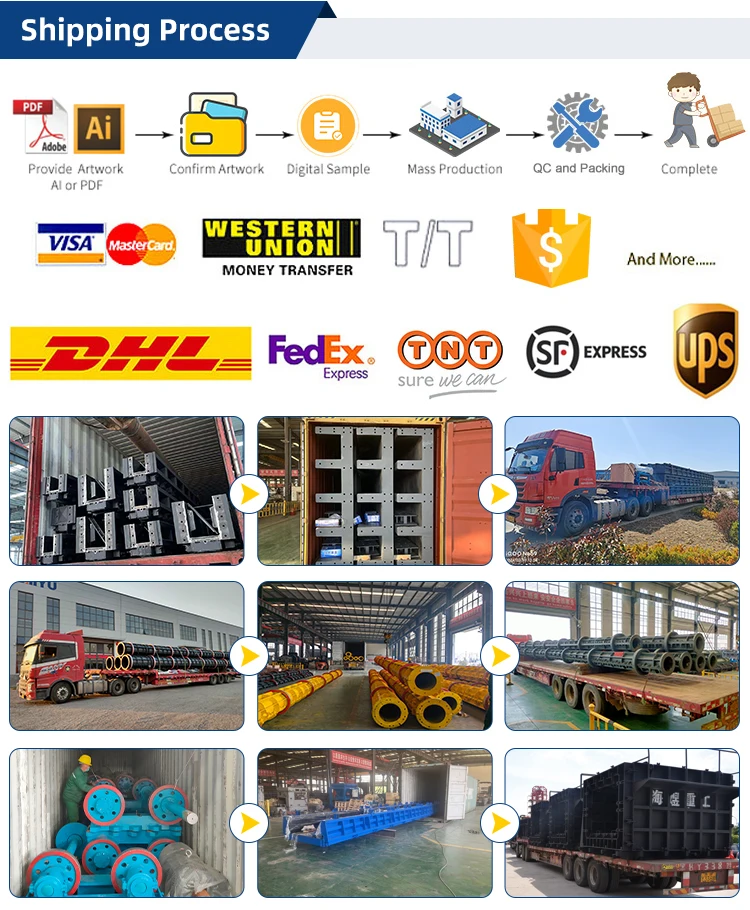

Q:Do you have set up an independent factory? A:We have our own factory. Has the specialized cement machinery product equipment factory, also has the large-scale cement drain pipe production factory.

Q:What can you do for us? A:1. Before sales can be targeted to give some constructive Suggestions. 2.Make a specific plan for your needs. 3. After sales reference specific products, different products have different services. Refer to the specific product description.

Q: Can you do the basic design for us? A: Yes, we have a professional team with rich experience in basic design of cement pipe making equipment with CAD software. You just need to tell us your ideas and requirements, and we will provide you with the most perfect design.

Q:Can your engineers train our workers in our factories? A:Yes, we have a very large engineering installation team that can train and instruct your workers to operate the installation equipment.

Q:If we provide the parameter requirements, can we make it to order? A:We provide customized services as long as you provide the appropriate drawings and product requirements.

Q:How long is your lead time? A:Our delivery time varies according to the quantity of the order, usually around 30 days.