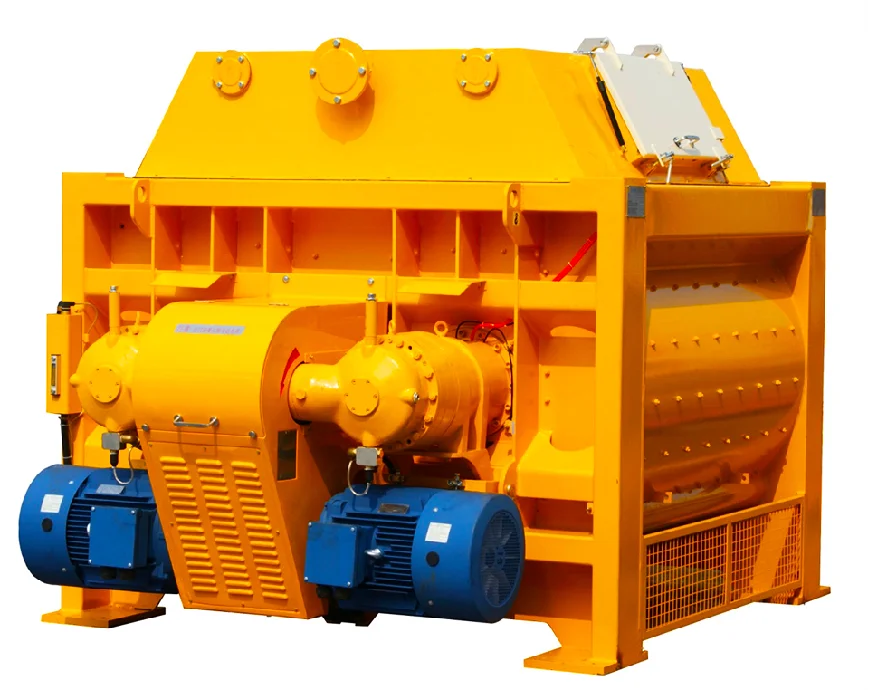

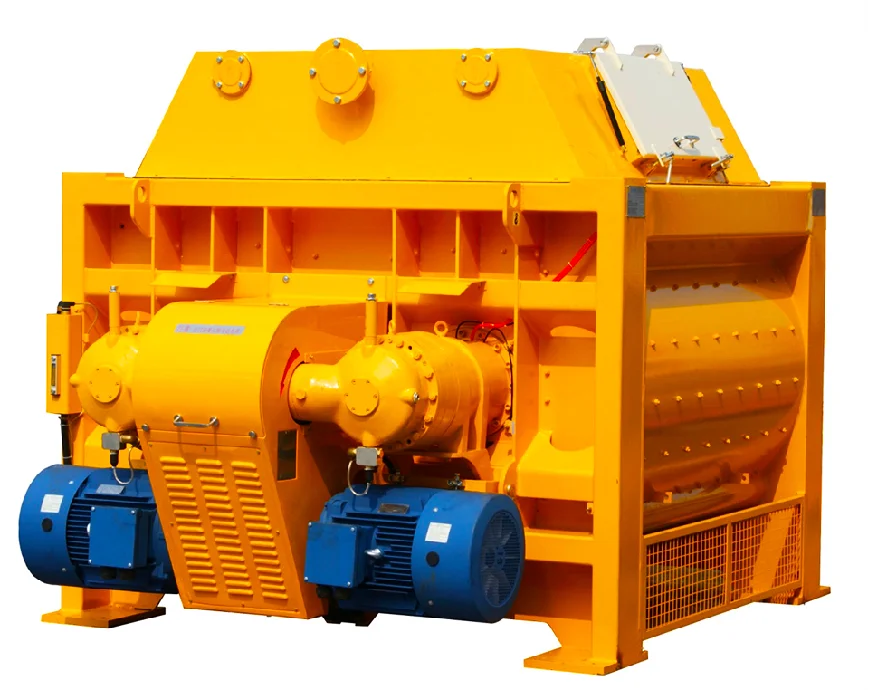

The twin-shaft mixer is a highly efficient mixing equipment widely used in construction,infrastructure,and concrete mixing plants.It achieves uniform mixing of materials quickly through the counter-rotating twin shafts and mixing blades. This product is designed with advanced concepts and manufactured with high-quality processes to ensure high mixing efficiency,low energy consumption, along service life.

Description

Pacific High-efficiency Twin-shaft Mixer for Concrete Mixing

Product introduction:

|

Technical Parameter

|

||||||||||||

|

Model

|

JS 750

|

JS 1250

|

JS 1500

|

JS 2000

|

JS 3000

|

JS 4000

|

||||||

|

Charging capacity(L)

|

1200

|

2000

|

2400

|

3200

|

4800

|

6400

|

||||||

|

Discharging capacity(L)

|

750

|

1250

|

1500

|

2000

|

3000

|

4000

|

||||||

|

Production capacity(m3/h)

|

42

|

75

|

90

|

120

|

180

|

240

|

||||||

|

Mixing axle rotation speed(r/min)

|

29.9

|

29.67

|

26.75

|

23.5

|

23.4

|

22.85

|

||||||

|

Mixer motor power(kw)

|

2*15

|

2*22

|

2*30

|

2*37

|

2*55

|

2*75

|

||||||

|

Librication oil pump

motor power(kw)

|

0.09

|

0.09

|

0.09

|

0.09

|

0.09

|

0.09

|

||||||

|

Hydraulic system

motor power(kw)

|

2.2

|

2.2

|

2.2

|

2.2

|

2.2

|

2.2

|

||||||

|

Electromagnetism valve

power supply(V)

|

DC24

|

DC24

|

DC24

|

DC24

|

DC24

|

DC24

|

||||||

|

Mixing time(s)

|

<=40

|

<=40

|

<=40

|

<=40

|

<=45

|

<=45

|

||||||

|

No. of mixing arm

|

12

|

12

|

16

|

16

|

18

|

22

|

||||||

|

Max diameter of

aggregate(Detritus/

Pebble)

|

60/80

|

60/80

|

60/80

|

80/120

|

100/150

|

100/150

|

||||||

|

External dimensions(LxWxH)

|

2900x

2650x

2100

|

3000x

2750x

2100

|

2900x

3000x

2150

|

3450x

3000x

2150

|

3900x

3300x

2230

|

4500x

3310x

2230

|

||||||

|

Transportation dimensions(LxWxH)

|

2900x

2100x

2100

|

3000x

2100x

2100

|

2900x

2320x

2150

|

3450x

2320x

2250

|

3900x

2600x

2230

|

4500x

2600x

2230

|

||||||

|

Entire machine weight(kg)

|

5000

|

5300

|

6500

|

7500

|

9300

|

11800

|

||||||

Product features:

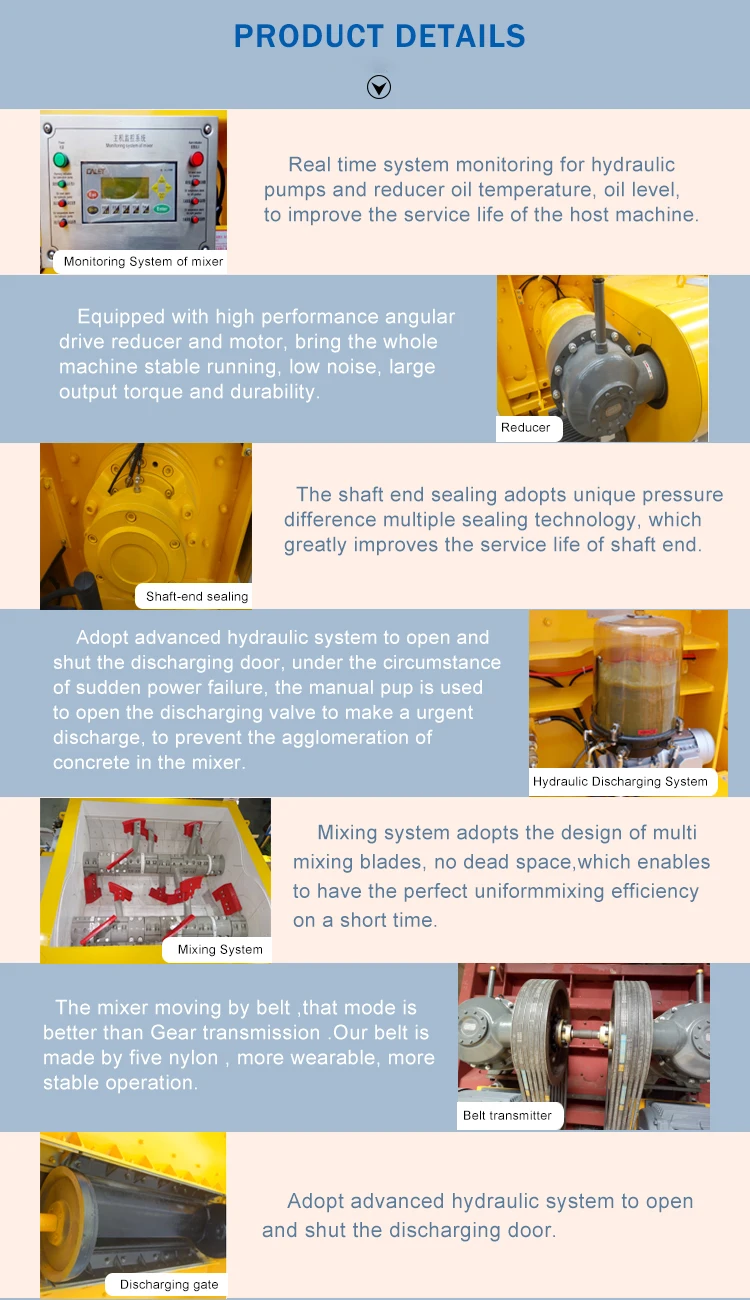

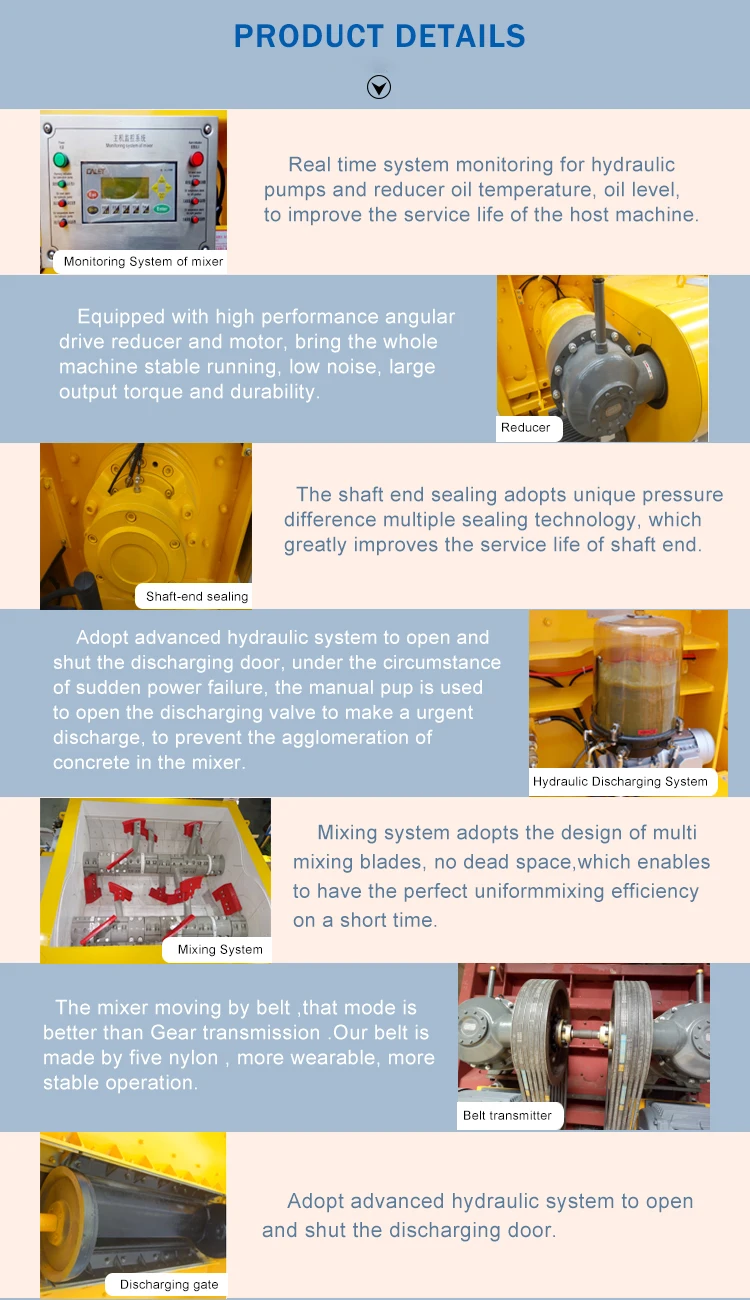

1.High mixing efficiency: Optimized blade design and phase angles create complex material movement within the mixing drum for quick and uniform mixing.

2.Durability: Mixing arms and blades are made of high-strength wear-resistant materials for long service life.

3.Smart monitoring: Equipped with an intelligent monitoring system that tracks equipment operation in real-time and identifies potential faults.

4.Easy maintenance: The shaft end seal uses a floating oil seal principle,ensuring reliable sealing performance and easy maintenance.

5.Convenient discharge: The hydraulic discharge system efficiently removes materials,and the well-designed discharge door prevents material accumulation.

Company advantages:

1.Technological leadership: Adopting advanced German technology and optimizing it to meet domestic needs.

2.Rich experience: With years of experience in manufacturing mixing equipment and strict quality control.

3.One-stop service: Offering comprehensive services from R&D and production to after-sales support to meet customer-specific needs.

4.Brand reputation: As a well-known brand in the industry,our products enjoy a good reputation in the market.

After-sales service:

1.Quick response: Respond to customer inquiries within 24 hours and solve technical issues promptly.

2.Technical Support: Provide remote technical guidance and on-site installation and commissioning services.

3.Spare parts supply: Offer original spare parts for a long period to ensure the normal operation of the equipment.

4.Training services: Provide operation and maintenance training to help customers use the equipment better.

FAQ

Q: Are you factory or a trading company? A: We are factory and a professional manufacture of concrete batching plant and cement silos. Q: What's your advantage? A: We are a young and active thinking group, we can design and also can advise special design according the clients detail requirements. Q: How about your producr quality? A: We are a factory that only do export, we must keep the high quality product to reduce the after-sale service cost. Q: Do you supply training and after-sale service? A: Yes,we will supply installation and training on site and also we have a professional service team that can solve all the problems as fast as possible. Q: How about your price? A: We will promise that you will get what you pay. Q: Do you have CE certificate for your concrete batching plant / cement silo? A: Yes, we have. Both are our patent products, certificated by CE.