Description

JS1250 1500 2000 3000 4500 Twin Shafts Horizontal Concrete Mixer for Mixing Plants

Product Introduction

JS Series Standard Twin-shaft Concrete Mixer

inspired by advanced technologies from home and abroad.Ever since it was sold into the market,its stable performance and excellent quality have quickly won the trust of majority of users.Now it has become our star products.It is mainly used in the mixing plants of high speed railways,expressways,airports, hydro-power stations,commercial concrete and so on.

Advantages of JS series Twin Shafts Mixer

1. High mixing efficiency, good uniformity;

2. The use of new patented sealing technology, sealing effect, long service life;

3. The use of advanced imported reducer or high reliability reducer (optional);

4. The top automatic lubrication pump, centralized lubrication, to ensure that the shaft seal more durable;

5. Power "security lock" design, from the respect for life;

6. Exquisite manufacturing process.

Advantages of JS series Twin Shafts Mixer

1. High mixing efficiency, good uniformity;

2. The use of new patented sealing technology, sealing effect, long service life;

3. The use of advanced imported reducer or high reliability reducer (optional);

4. The top automatic lubrication pump, centralized lubrication, to ensure that the shaft seal more durable;

5. Power "security lock" design, from the respect for life;

6. Exquisite manufacturing process.

Technical Parameters

|

Technical Parameter

|

||||||||||||

|

Model

|

JS 750

|

JS 1250

|

JS 1500

|

JS 2000

|

JS 3000

|

JS 4000

|

||||||

|

Charging capacity(L)

|

1200

|

2000

|

2400

|

3200

|

4800

|

6400

|

||||||

|

Discharging capacity(L)

|

750

|

1250

|

1500

|

2000

|

3000

|

4000

|

||||||

|

Production capacity(m3/h)

|

42

|

75

|

90

|

120

|

180

|

240

|

||||||

|

Mixing axle rotation speed(r/min)

|

29.9

|

29.67

|

26.75

|

23.5

|

23.4

|

22.85

|

||||||

|

Mixer motor power(kw)

|

2*15

|

2*22

|

2*30

|

2*37

|

2*55

|

2*75

|

||||||

|

Librication oil pump

motor power(kw)

|

0.09

|

0.09

|

0.09

|

0.09

|

0.09

|

0.09

|

||||||

|

Hydraulic system

motor power(kw)

|

2.2

|

2.2

|

2.2

|

2.2

|

2.2

|

2.2

|

||||||

|

Electromagnetism valve

power supply(V)

|

DC24

|

DC24

|

DC24

|

DC24

|

DC24

|

DC24

|

||||||

|

Mixing time(s)

|

<=40

|

<=40

|

<=40

|

<=40

|

<=45

|

<=45

|

||||||

|

No. of mixing arm

|

12

|

12

|

16

|

16

|

18

|

22

|

||||||

|

Max diameter of

aggregate(Detritus/

Pebble)

|

60/80

|

60/80

|

60/80

|

80/120

|

100/150

|

100/150

|

||||||

|

External dimensions(LxWxH)

|

2900x

2650x

2100

|

3000x

2750x

2100

|

2900x

3000x

2150

|

3450x

3000x

2150

|

3900x

3300x

2230

|

4500x

3310x

2230

|

||||||

|

Transportation dimensions(LxWxH)

|

2900x

2100x

2100

|

3000x

2100x

2100

|

2900x

2320x

2150

|

3450x

2320x

2250

|

3900x

2600x

2230

|

4500x

2600x

2230

|

||||||

|

Entire machine weight(kg)

|

5000

|

5300

|

6500

|

7500

|

9300

|

11800

|

||||||

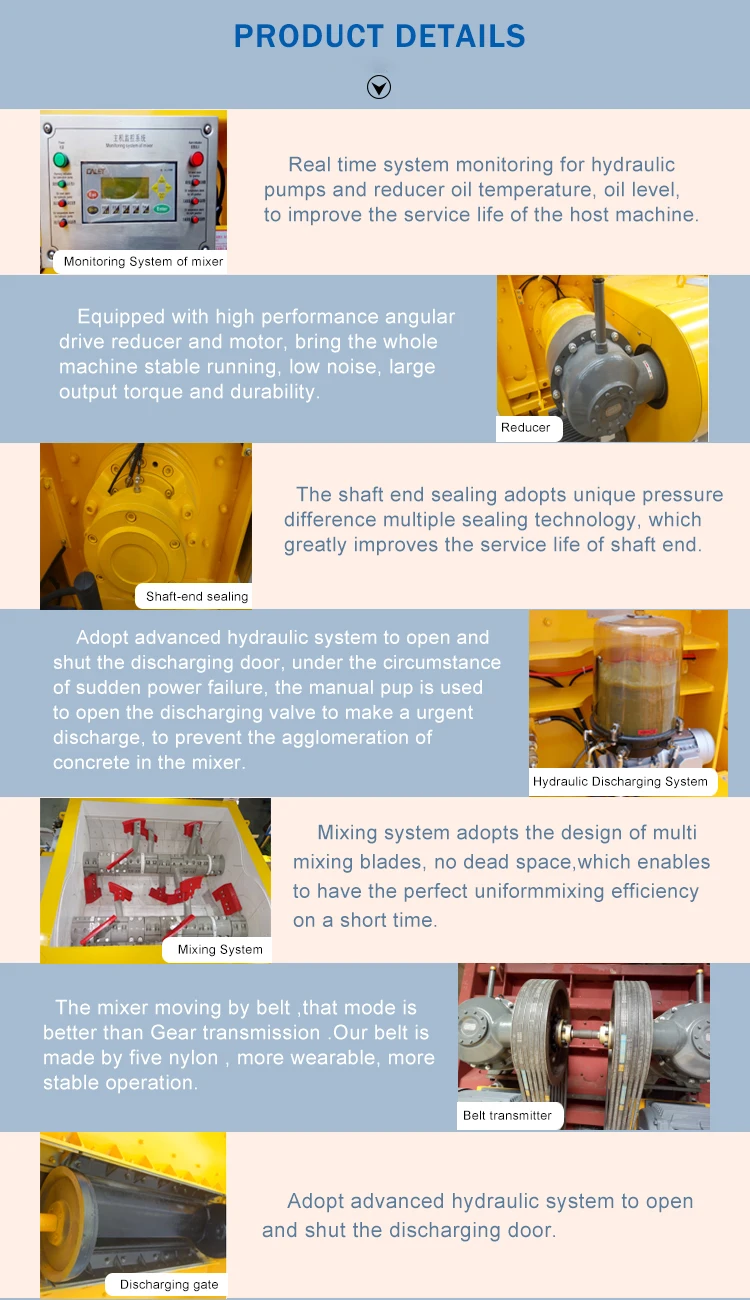

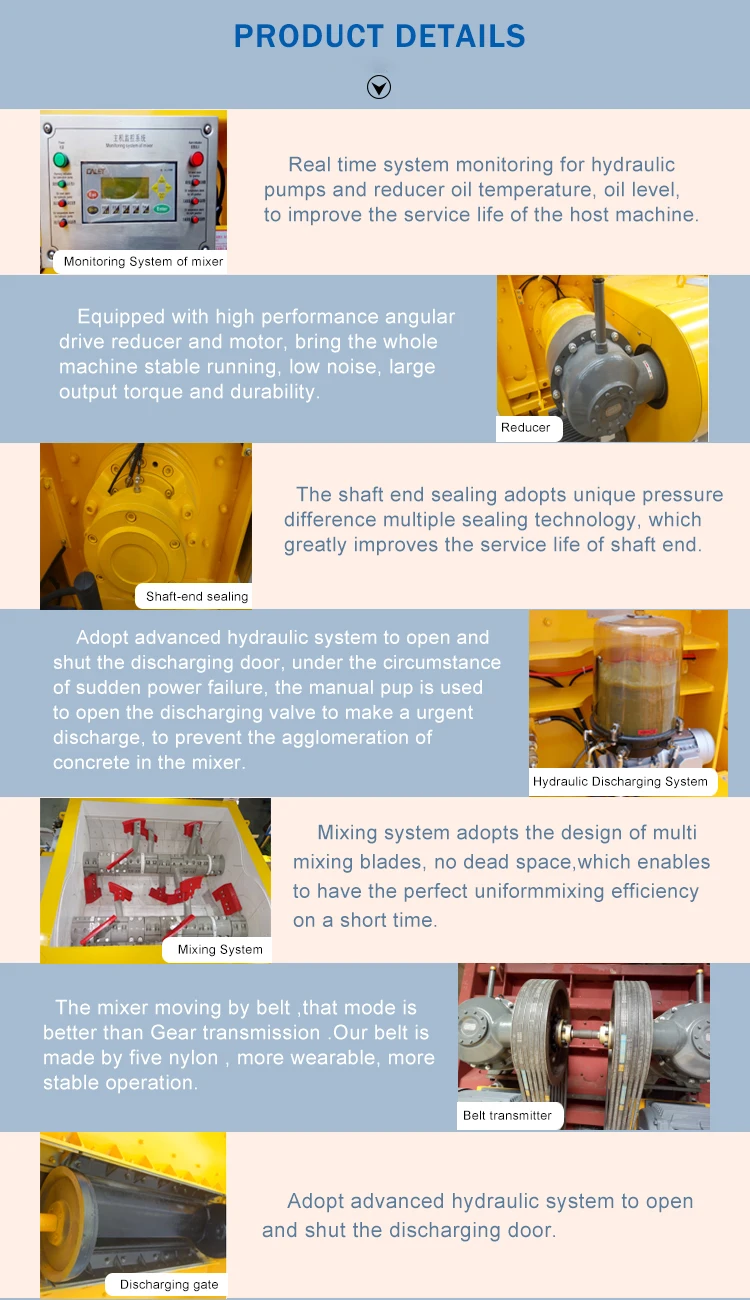

Production Features

Package and shipping

Company Profile

Contact us

FAQ

FAQ

Q: Are you factory or a trading company? A: We are factory and a professional manufacture of concrete batching plant and cement silos. Q: What's your advantage? A: We are a young and active thinking group, we can design and also can advise special design according the clients detail requirements. Q: How about your producr quality? A: We are a factory that only do export, we must keep the high quality product to reduce the after-sale service cost. Q: Do you supply training and after-sale service? A: Yes,we will supply installation and training on site and also we have a professional service team that can solve all the problems as fast as possible. Q: How about your price? A: We will promise that you will get what you pay. Q: Do you have CE certificate for your concrete batching plant / cement silo? A: Yes, we have. Both are our patent products, certificated by CE.