Description

Concrete pile equipment

|

No.

|

Inner Diameter/mm

|

Distance of wheels/mm

|

Diameter of Wheels/mm

|

Length/m

|

|

1

|

∅300

|

2000

|

∅600

|

7~11

|

|

2

|

∅400

|

2000

|

∅640

|

7~12

|

|

3

|

∅500

|

2000

|

∅740

|

7~15

|

|

4

|

∅600

|

2000

|

∅840

|

7~15

|

|

5

|

∅700

|

2000

|

∅1000

|

7~39

|

|

6

|

∅800

|

2000

|

∅1100

|

7~60

|

|

7

|

∅1000

|

2000

|

∅1300

|

7~60

|

|

8

|

∅1200

|

2000

|

∅1500

|

7~60

|

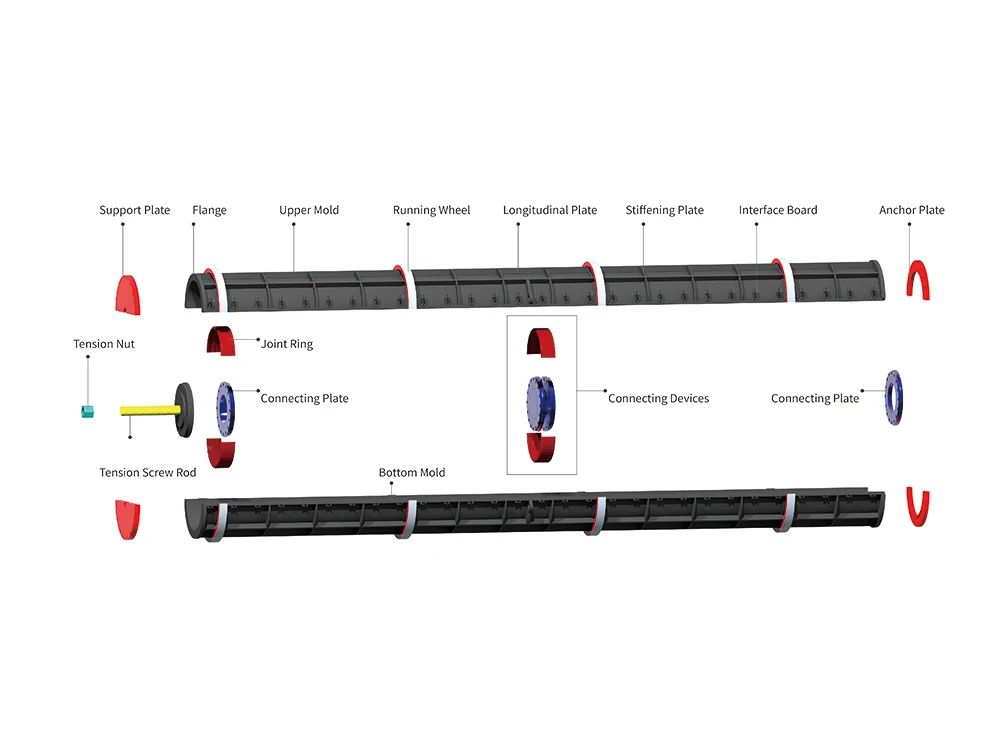

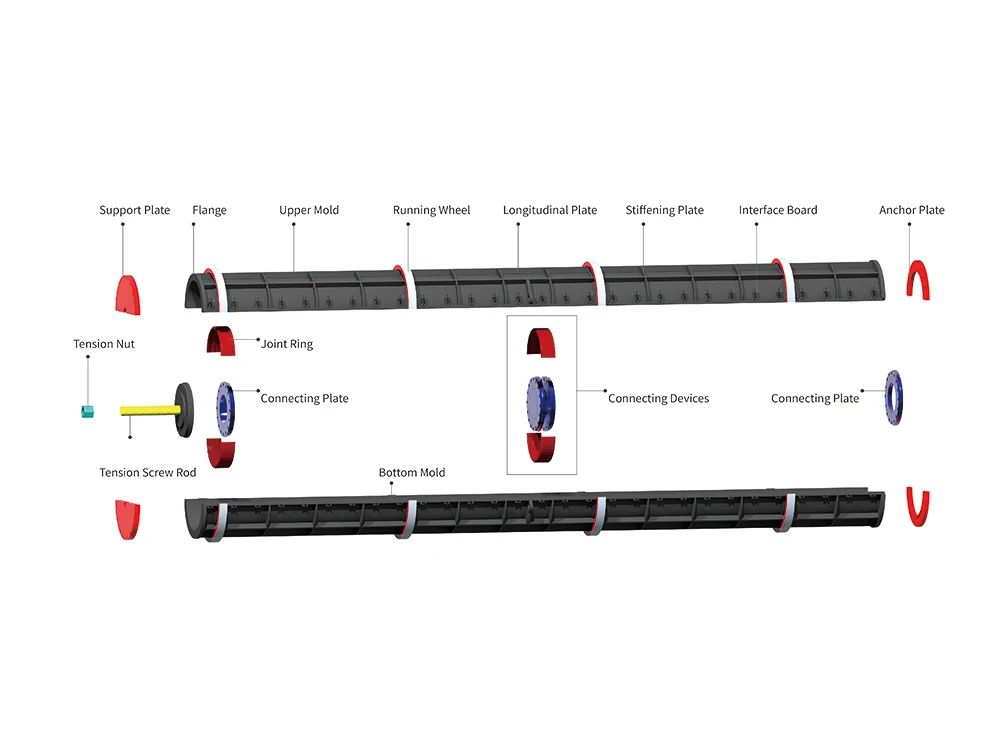

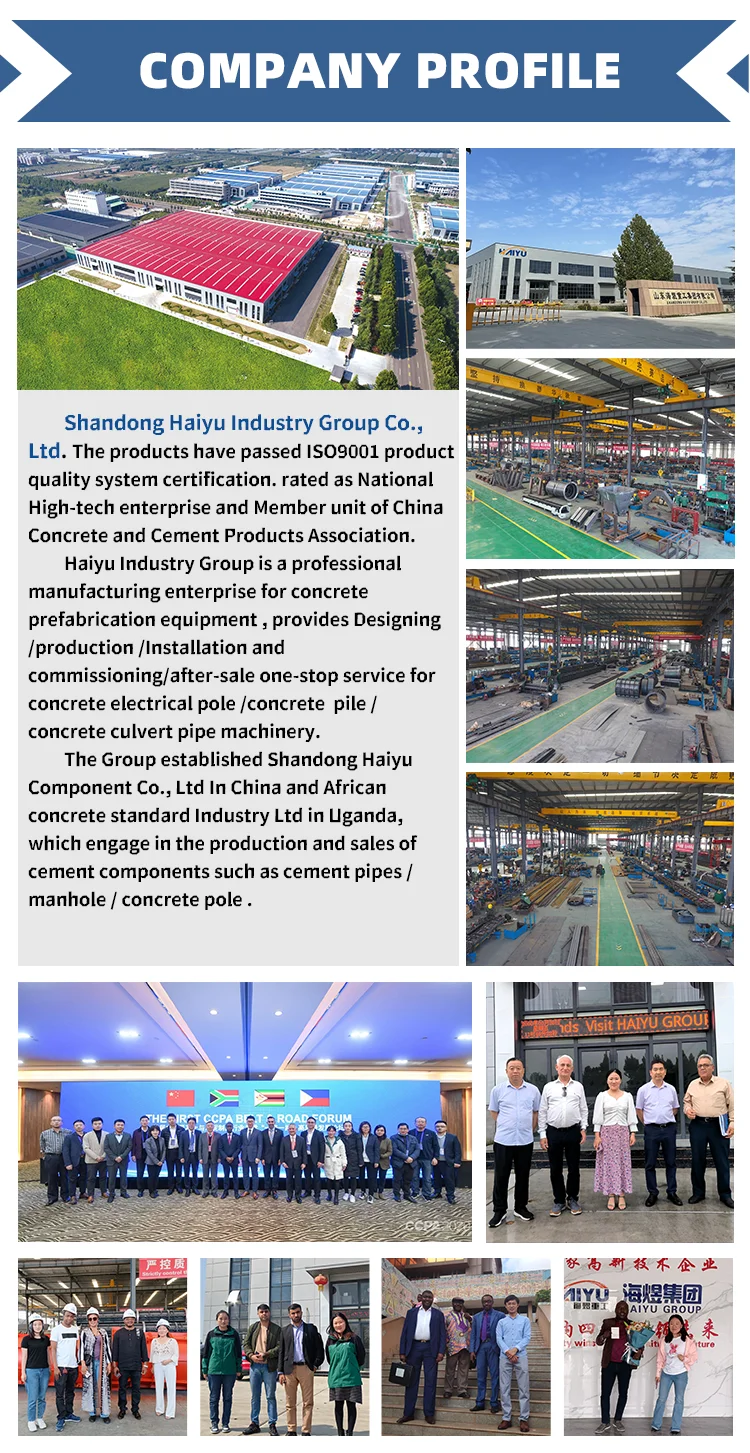

Advantages of steel mold

1. The steel mold tongue and groove plate is processed by milling machine, which improves the production efficiency and quality stability. 2. The 18m long lathe is introduced, and the specifications below ø1000mm X15.4M can be processed as a whole, which improves the concentricity of the steel mold. 3. The steel mold adopts the section welding process, the welding process is carbon dioxide shielded welding, the gas uses mixed gas, and the welding machine adopts Panasonic welding machine, the solder joints are beautiful and there is no welding slag. 4. The material of the running wheel is 30Mn, which has good wear resistance. 5. The maximum length of the cylinder is 12m, and there are few weld seams in the cylinder, which reduces the influence of welding deformation and the error of manual docking. The material can be selected from Q235B or Q345B. 6. The size of ribs and flanges can be configured according to customer requirements, and sizes such as 12×63mm or 20×63mm can be selected.

Product advantages

1. The segmented pile formwork produced by our company is assembled as a whole, easy to transport, quick to assemble, easy to maintain, strong in structure and high in tensile strength. It can realize multiple functions in one mold, which greatly saves the investment cost for customers. 2. Our company's wire rod steel mold adopts thickened end plates and flanges, with stable connection, strong tension, overall longitudinal ribs, good stability, and the pipe body is not easy to deform. 3. The integral lifting ring is adopted, which is safe and reliable, and the thickened running wheel improves the product quality and prolongs the service life. 4. Other equipment required for the prestressed pipe pile production line equipment, such as driving, transport trolley, feeding machine, mixing station, steam curing pool, boiler room, automatic piling system for finished products, wire winding machine, etc. are all well-known domestic and high-quality Stable and reliable supplier equipment or self-manufactured by our factory, reliable and stable after-sales guarantee, users can use it comfortably and at ease. 5. Reinforced concrete prefabricated pile technology is widely used in most building constructions due to its strong technical advantages.

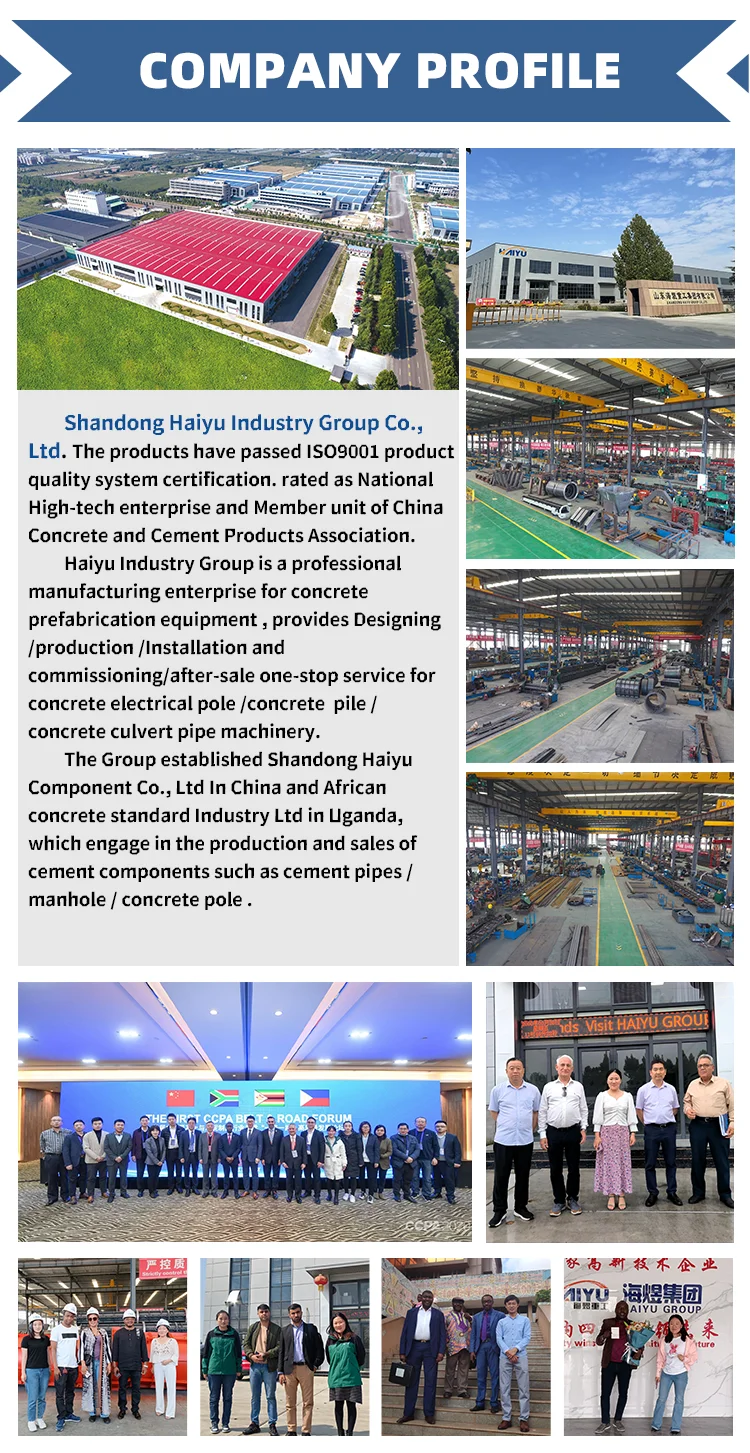

Q:Do you have set up an independent factory? A:We have our own factory. Has the specialized cement machinery product equipment factory, also has the large-scale cement drain pipe production factory.

Q:What can you do for us? A:1. Before sales can be targeted to give some constructive Suggestions. 2.Make a specific plan for your needs. 3. After sales reference specific products, different products have different services. Refer to the specific product description.

Q: Can you do the basic design for us? A: Yes, we have a professional team with rich experience in basic design of cement pipe making equipment with CAD software. You just need to tell us your ideas and requirements, and we will provide you with the most perfect design.

Q:Can your engineers train our workers in our factories? A:Yes, we have a very large engineering installation team that can train and instruct your workers to operate the installation equipment.

Q:If we provide the parameter requirements, can we make it to order? A:We provide customized services as long as you provide the appropriate drawings and product requirements.

Q:How long is your lead time? A:Our delivery time varies according to the quantity of the order, usually around 30 days.